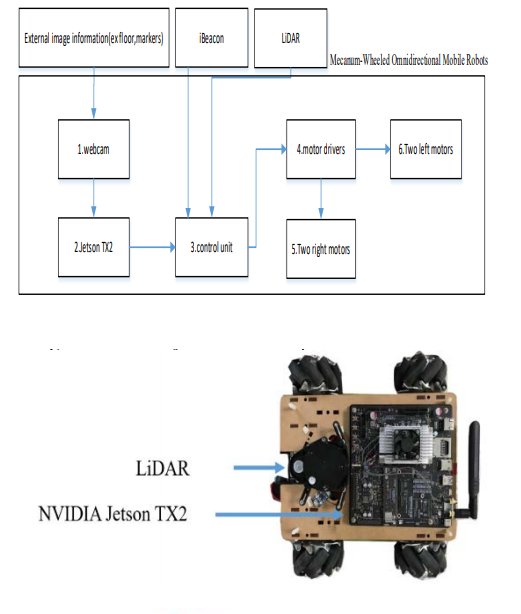

We have been seeing an increase in the number of beacon-based employee clocking in/out systems. This is due to a recent ruling by the European Court of Justice that said that EU companies must have something in place to provide an “objective, reliable and accessible system” that allows the duration of time worked each day to be measured. This is so that it can be confirmed that companies and organisations are complying with the Fundamental Rights Charter and the Working Time Directive.

Some employers and employers’ federations have been critical of the need for modern versions of the ‘punch card’. Some employees also resent being tracked to such a degree. In today’s mobile, flexible working environments, it’s often not practical to track work-related activities performed outside the main workplace. The definition of work is also open to interpretation. For example, is replying to a work email, at home, outside working hours, counted as work?

As with many EU rules, these things can’t be clearly defined and aren’t properly policed. In this case, companies and organisations will come under scrutiny if employees or their unions go to court for non-compliance with working time regulations. Some industries such as construction need time tracking anyway for contractor billing and safety. It’s for each organisation to assess the risk. For those deciding they need time tracking, beacons provide an automated solution.