In the early days of Bluetooth beacons, many businesses were excited about the prospect of sending unsolicited messages directly to people’s phones as they walked by. This was once possible through the Google Nearby service, a feature that allowed notifications to be sent to users without the need for an app. However, in 2018, Google shut down the Nearby service, effectively ending unsolicited beacon messaging. Since then, the way we interact with Bluetooth beacons has evolved significantly.

Today, if you want to notify users through a beacon, you need an app. This app must be capable of detecting nearby beacons and presenting relevant information to the user. For businesses and developers, this means you have a few options. You could modify an existing app to detect beacons, create a new app from scratch, or use a third-party app specifically designed for this purpose such as CliqTags.

CliqTags offers two versatile app, CliqTags Nearby and CliqTags Spotter, that help businesses use the power of Bluetooth beacons:

CliqTags Nearby: Simple, Seamless, and Independent

CliqTags Nearby is an app that uses the Eddystone-URL advertising format to detect beacons and display site information directly to users. Unlike Google’s old Nearby implementation, CliqTags Nearby fetches information directly from the site, making it a seamless and independent experience. Users can click the button to visit the site directly, without relying on any external services, not even CliqTags. The app is available for free on both Google Play and the Apple App Store, and it can be private-branded and customised to meet specific business needs.

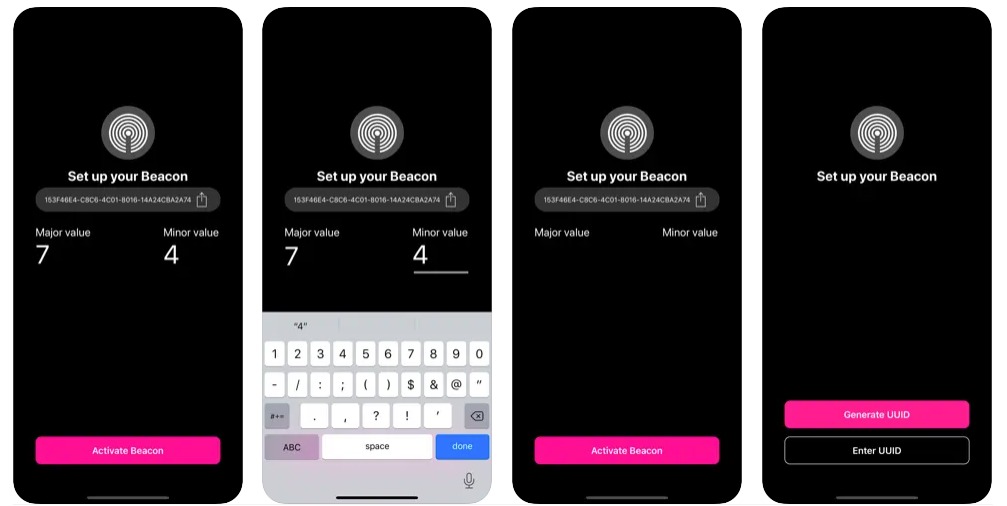

CliqTags Spotter: Advanced Functionality with iBeacon Technology

CliqTags Spotter takes things a step further by using iBeacon technology. When an iBeacon is detected, the app communicates with the CliqTags server to translate the iBeacon ID into a corresponding website. One of the standout features of CliqTags Spotter is its ability to reconfigure beacon IDs over time, allowing different content to be associated with the same beacon. This flexibility extends to geofencing, providing a level of control that businesses can manage via the CliqTags server. Due to its complexity and customisability, CliqTags Spotter isn’t available in app stores. Instead, it’s offered as a private-branded solution tailored to the specific needs of businesses.