There’s lots said about the advantages of Industry 4.0 or Digital Transformation and the associated new technologies but it’s a lot harder to apply this to the context of a business that has legacy equipment and no real way of knowing where to start.

Our previous article on productivity explained how, historically, digital transformation has been only been implemented in the top 5% ‘frontier’ companies. These have tended to be very large companies with large R&D budgets that have enabled customised digital solutions. More recently, the availability of less expensive sensors and software components have extended opportunities to the SME companies. These companies are already realising gains in profitability, customer experience and operational efficiency. Unlike previous technologies, such as CRM, the newer technologies such as IoT and AI are more transformative. Companies that don’t update their processes risk being outranked by their competition with a greater possibility of going out of business. But where do you start?

The place to start is not technology but instead something you and your colleagues fortunately have lots of experience of : Your company. Take an honest look at your processes and work out the key problems that, if solved, would achieve the greatest gains. You might have ignored problems or inefficiencies for years or decades because they were thought to be insolvable. Technology might now be able to solve some of these problems. So what kind of problems? Think in terms of bottlenecks, costly workrounds, human effort-limited tasks, stoppages, downtimes, process delays, under-used equipment and even under-used people. Can you measure these things and react? Can you predict they are about to happen? This is where sensing comes in.

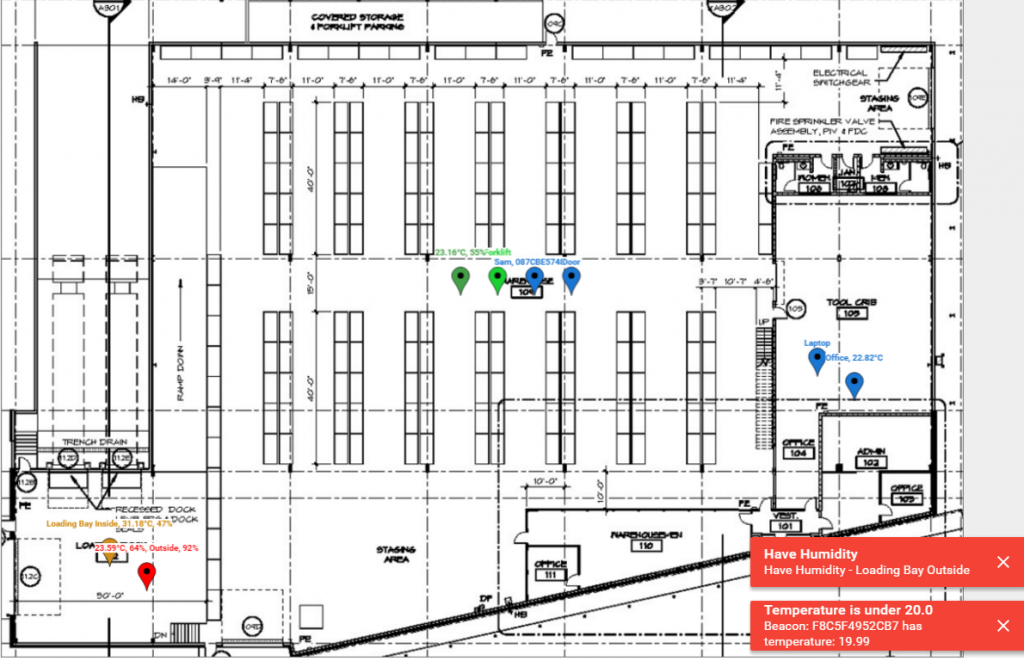

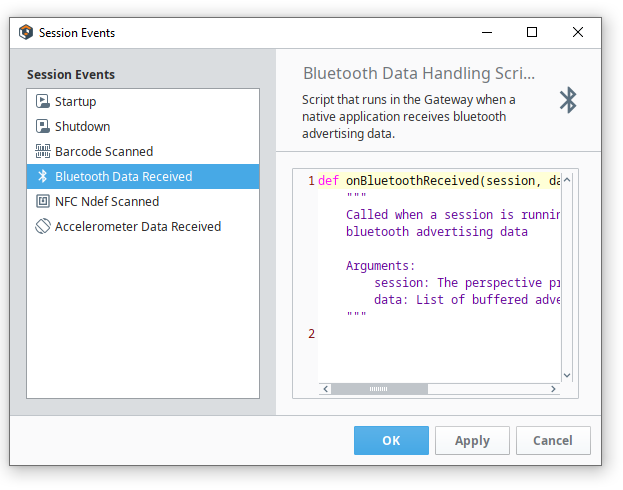

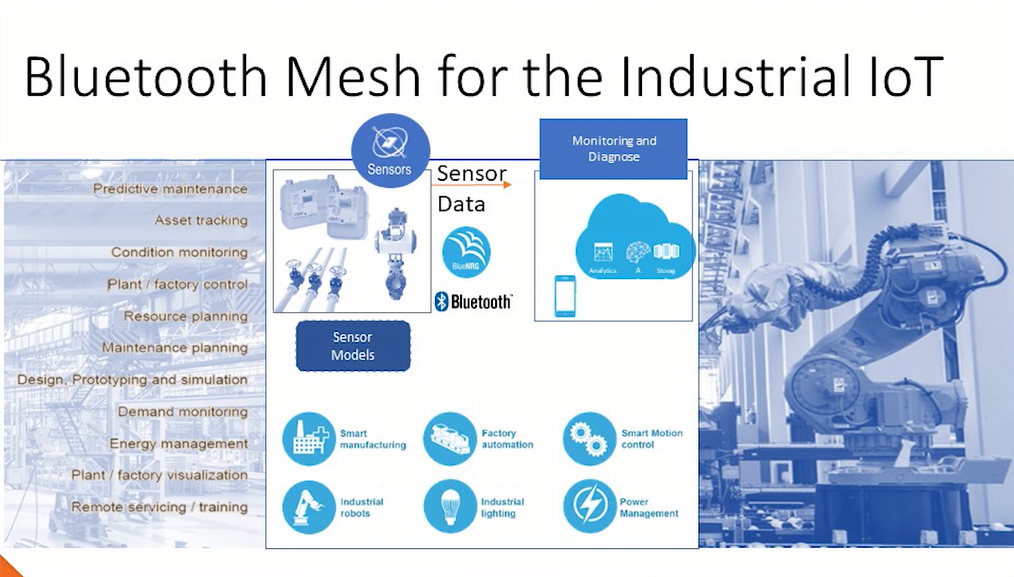

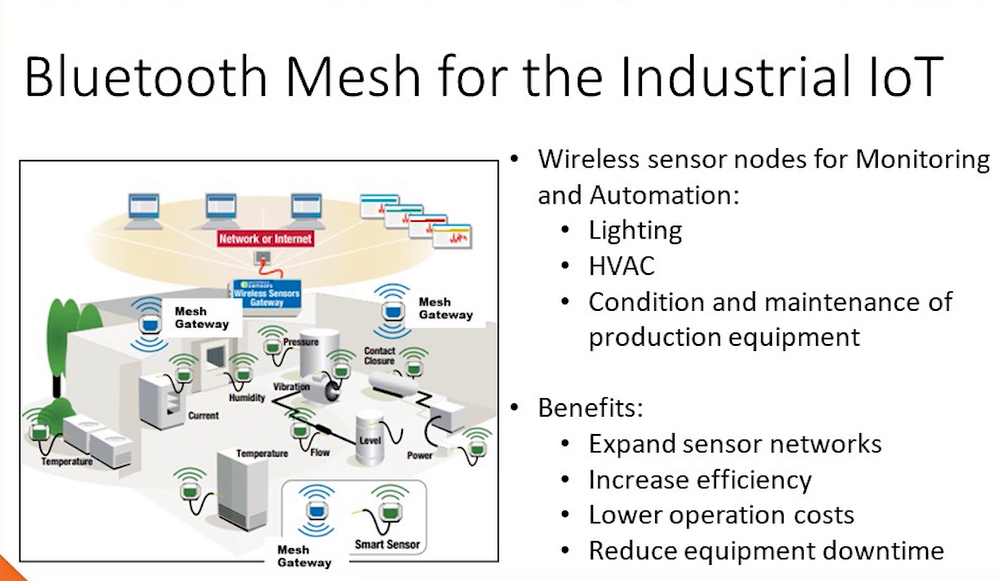

The next stage is connectivity. You will almost certainly need to upgrade or expand your WiFi and/or Ethernet network. It can be impractical to put sensors on everything and everyone and connect everything by WiFi/Ethernet. Instead, consider Bluetooth LE and sensor beacons to provide a low cost, low power solution for the last 50 to 100m. Bluetooth mesh can provide site-wide connectivity.

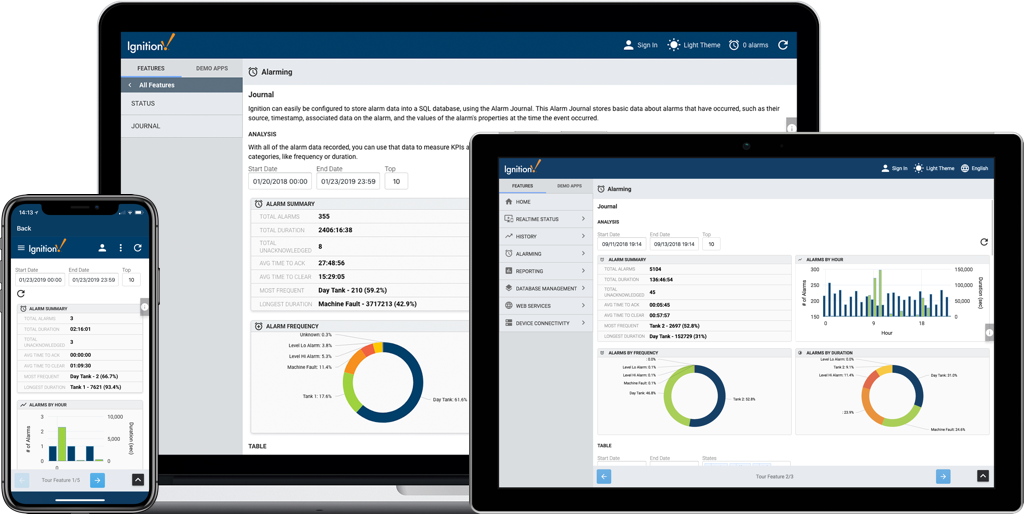

Initially implement a few key improvements that offer good payback for the effort (ROI). The improvements in efficiency, productivity, reduced costs and even customer experience should be enough to convince stakeholders to expand and better plan the digital transformation. This involves replacement of inefficient equipment and inefficient processes using, for example, robotics and 3D printing. It also involves analysing higher order information combined from multiple sources and using more advanced techniques such as AI machine learning to recognise and detect patterns to detect, classify and predict. This solves problem complexity beyond that able to be solved by the human mind or algorithmic program created by a programmer.

Get Help Determining Feasibility

Read about Beacons in Industry and the 4th Industrial Revolution (4IR)

Explore AI Machine Learning with Beacons