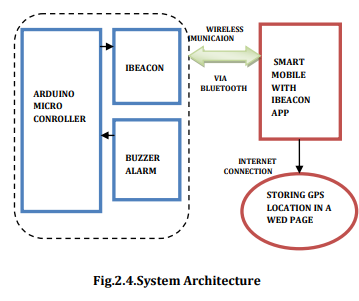

Connected factory implementations require a large number of connected assets for condition-based monitoring, asset tracking, inventory (stock) management or for building automation. Bluetooth is a secure, low cost, low power and reliable solution suitable for use in connected factories. In this post, we examine the reasoning behind some out-of-date thinking on industrial wireless, uncover the real problems in factories and provide some explanations how Bluetooth overcomes these challenges.

Operations teams are usually very sceptical about industrial wireless. They have usually tried proprietary industry solutions using wireless with mixed results. They might have experienced how connections, such as WiFi, can become unreliable in the more electrically noisy areas of factories. The usual approach is to use cable. However, this can become expensive and time consuming. Using cable isn’t possible when assets are moving and becomes impractical when the number of connected items becomes large as in the case of connected factories. As we shall explain, Bluetooth is intrinsically more reliable than WiFi even through they share the same 2.4GHz frequency band.

There’s usually lots of electrical noise in an industrial environment that tends to be one of two types:

- Electromagnetic radiation emitted by equipment. This typically includes engines, charging devices, frequency converters, power converters and welding. It also includes transmissions from other radio equipment such as DECT phones and mobile telephones.

- Multipath propagation which is reflection of radio signals off, usually metallic, surfaces and received again slightly later.

It’s important to understand how Bluetooth and other competing technologies react to these types of interference. There’s a useful study (pdf) by Linköping University, Swedish Defence Research Agency (FOI) and the University of Gävle on noise industrial environments.

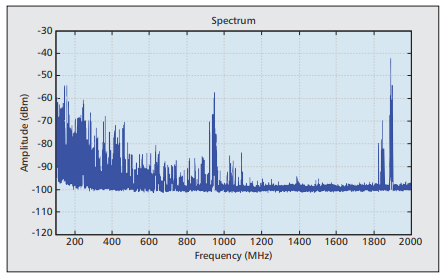

Noise in industrial environments tends to follow the following spectral pattern:

There’s usually lots of electrical noise up to about 500MHz. This means wireless communication using lower frequencies, such as two way radio, exhibits a lot of noise. Pertinently, several wireless solutions for industrial applications use frequencies in the 30–80 MHz and 400–450 MHz bands. Bluetooth’s and WiFi’s 2.4GHz frequency is well above 500MHz so exhibits better reliability than some industrial wireless solutions. Incidentally, in the above charts, the peaks around 900 MHz and 1800 MHz mobile phone signals and 1880–1890 MHz come from DECT phones.

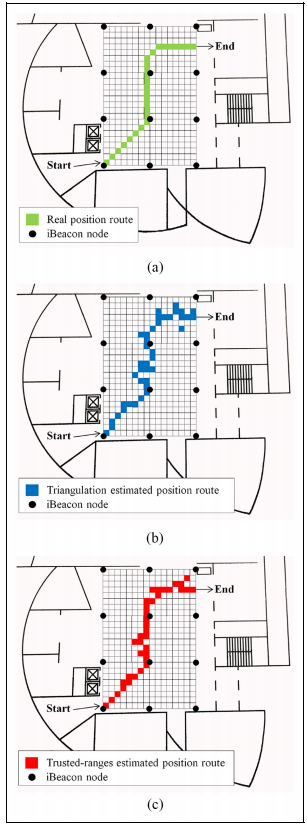

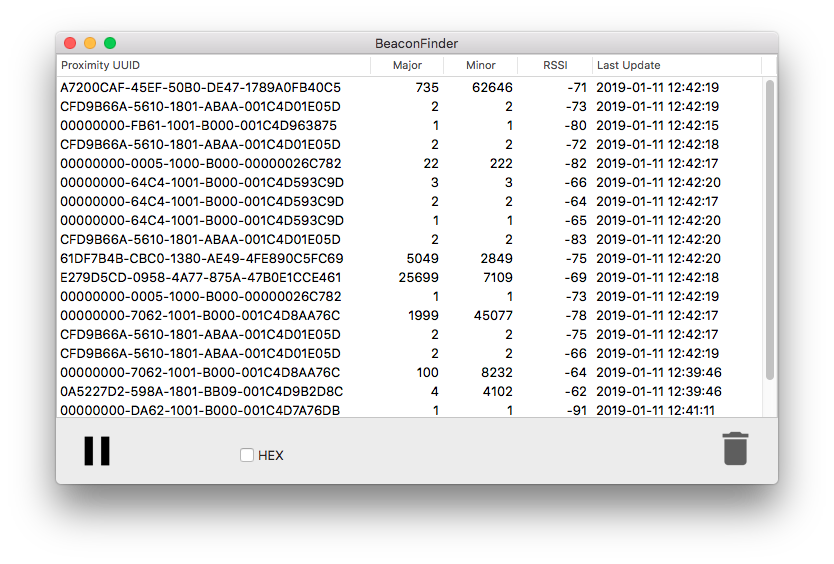

The magnitude of multipath propoagation depends on the environment. It’s greatest in buildings having highly reflective, usually metallic, floors, walls and roofs. If you imagine a radio signal wave being received and then received again nanoseconds later, you can imagine how both the amplitude (peaks) and the phase of the received signal becomes distorted over time. Bluetooth uses Adaptive Frequency Hopping (AFH) which means that packets transferred consecutively in time do not use the same frequency. Thus each packet acts like a single narrowband transmission and there’s less affect of one packet on the next one. However, what is more affected is amplitude which manifests itself as the received overall signal strength (RSSI). RSSI is often used by Bluetooth applications to infer distance from sender to receiver. We will mention mitigations for varying RSSI later.

It’s important to consider what happens when there is electrical noise. It turns out that technologies invented to ensure reliable transmission behave much less well in noisy situations. One such technique is carrier sense multiple access (CSMA), used by WLAN (WiFi), that listens to the channel before transmitting and waits until a free channel is observed. CSMA and automatic auto repeat (ARQ) also have re-transmission mechanisms. The retrying can also incur significant extra traffic that can overwhelm the communication in noisy environment. Bluetooth doesn’t use such schemes.

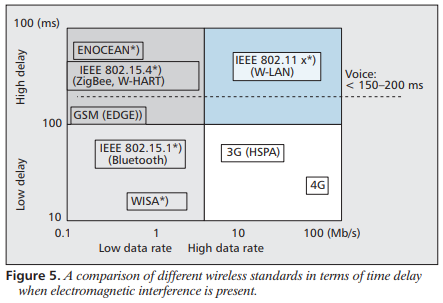

The previously mentioned research classifies different wireless technologies according to the delay when used in noisy environments:

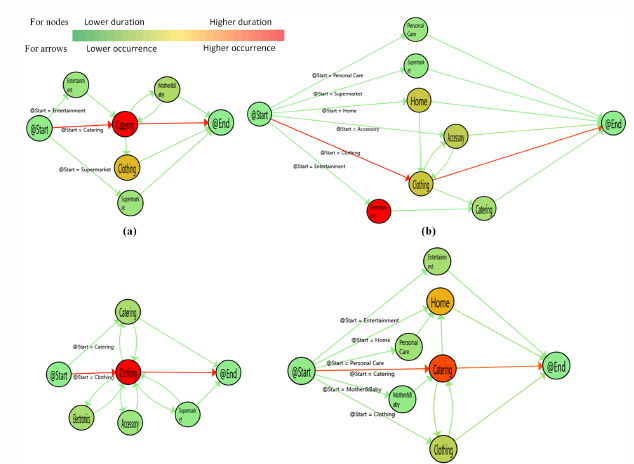

Bluetooth (and WISA) is a good choice for noisier environments. It’s particularly suited for applications with lower data rates and sending at periodic intervals.

A final consideration is interference between Bluetooth and other technologies, such as WiFi, that use similar 2.4GHz frequencies. As mentioned in a previous post, there’s negligible overlap between Bluetooth and WiFi channel frequencies.

In summary, Bluetooth is more suited to electrically noisy environments and also offers low cost, low power and secure wireless communication.

These conclusions correlate well with our own empirical observations. We have found that Bluetooth advertising is still received in environments we have measured, using a RF spectrum analyser, to be electrically noisy around 2.4GHz . We believe this is because Bluetooth advertising hops across three frequencies such that there’s less likelihood of noise on all three. Advertising is also very short, typically taking 1 or 2 ms, making the coincidence of the noise and the advertising less likely than would be the case of a longer transmission.

It has been our experience that solutions using Bluetooth advertising are more reliable than those using Bluetooth (GATT) connections, especially in noisy environments when it’s difficult to maintain the chatty protocol of a connection over a long time period. In noisy situations, advertising is usually seen on a future transmit/scan if the first advertising is lost. By coincidence or design, Bluetooth Mesh is built on communication via advertising rather than connection and for this reason is also reliable on the factory floor.

However, using Bluetooth isn’t a silver bullet. There are situations where factories, or more usually parts of factories, have reflective surfaces or unusual radio frequency (RF) characteristics stretching into unforeseen frequencies. Poorer performing WiFi also needs to be considered in context of choosing between Ethernet and WiFi gateways and Bluetooth mesh.

It’s important to do a site survey including RF spectral analysis. This will uncover nuances of particular critical locations or coverage that can drive subsequent hardware planning. It can also feed into requirements for software processing, for example particular settings for processing within a real time locating system (RTLS) to cater for more varying RSSI.

Consider a Feasibility Study if you need expert help.

Read about Beacons in Industry and the 4th Industrial Revolution (4IR)